Use

This equipment is suitable for the rotary forming processing (flaring, shrinking, etc.) of the copper pipe.

Features

- Using hydraulic, pneumatic and electrical control systems, full consideration of safety and other factors, convenient commissioning and simple operation, can fully meet the production of refrigeration pipe products, automatic completion of loading pipe and unloading pipe.

- The equipment control system has an automatic counting function, which can accurately count the processing quantity.

| NO. | Parameter items | Content |

| 1 | Pipe diameter range | Φ3.6-12.7mm |

| 2 | Pipe thickness range | 0.5-1.0mm |

| 3 | Pipe length range | 100-880mm |

| 4 | Work efficiency | 600-1000PCS/H |

| 5 | Number of stations | 2 cold punches + 1 straight punch |

| 6 | clamping method (cylinder Bore * Stroke) | Double force cylinder 100 * 50mm |

| 7 | Feed mode of punch (servo power * stroke) | 1KW*75mm |

| 8 | Length error | ≤0.25mm |

| 9 | Concentricity of main axis | ≤0.08mm |

| 10 | Processing methods | Rotate + cold punch |

| 11 | Drive method | Servo / Pneumatic |

| 12 | Feeding method | Auto feeding |

| 13 | Operation method | Auto / Manual / Jog |

| 14 | Electric control mode | CNC system |

| 15 | air pressure | 0.5~0.8MPa |

| 16 | Power mode | Three phase380V/50HZ |

| 17 | Overall dimensions (length X width X height) MM | 1600x800x1600 |

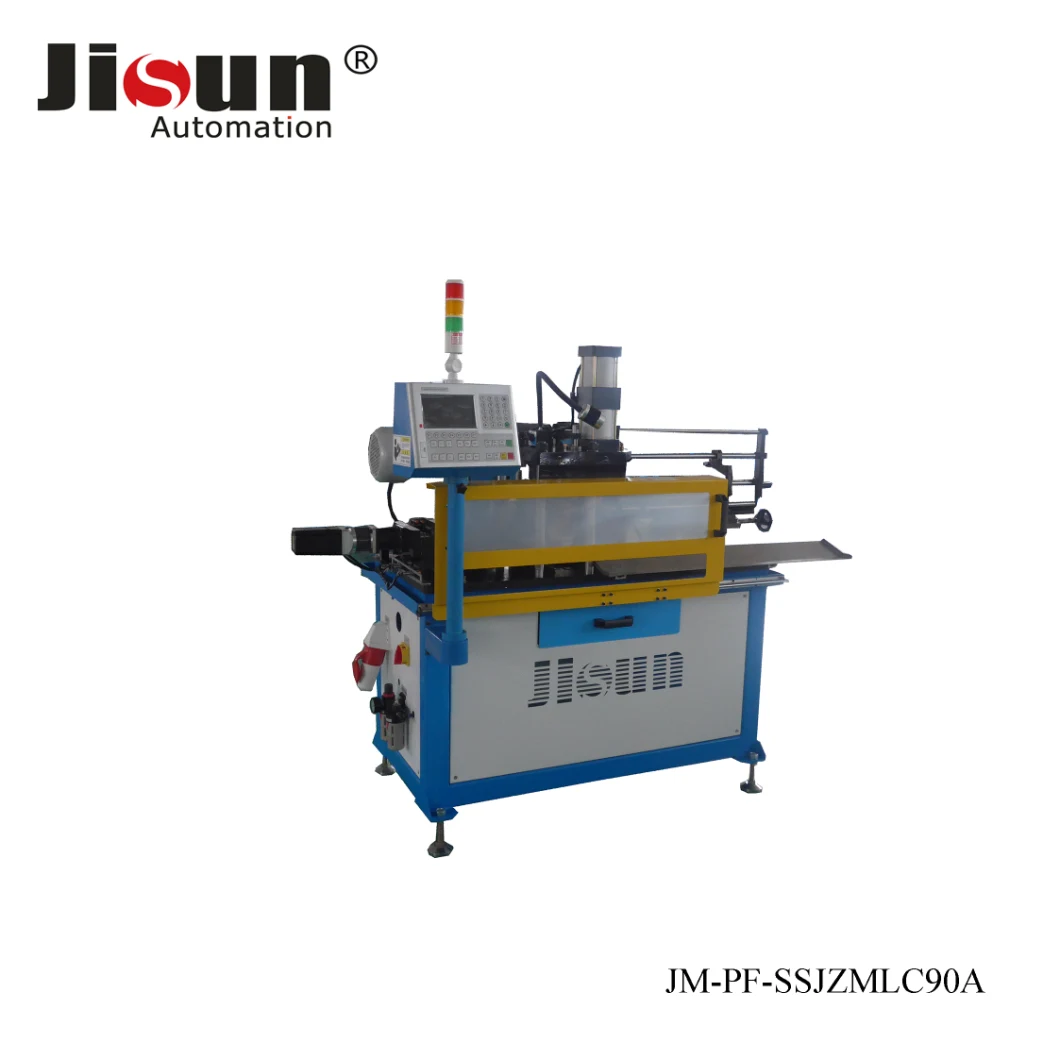

Equipment structure and system configuration

- Overview:The equipment consists of a frame, an air control system, a power head, a linear movement mechanism of the station, a servo system, and an electronic control system.etc.

- Frame: The fuselage is welded by profiles, and processed after vibration aging to ensure rigidity and accuracy of the mounting plane. It is equipped with four height-adjustable foot cups and safety protection doors;The parts of each part of the equipment are subjected to necessary surface treatments such as electroplating, blackening, quenching, carburizing, electrostatic spraying, etc. according to the actual working conditions and working environment to meet the components with sufficient strength and surface functions.

- Power head:Imported rotary boring head is used, with a maximum speed of 2800 rpm and a synchronous belt drive. The dual-axis feed is divided into two levels of fast forward and slow forward, and the feed speed and position are adjustable.

- Air control system: The compressed gas from an external source is purified by a precision water-gas separator. The pressure can be adjusted to provide a good gas environment for each circuit component. The precise position of the cylinder piston is controlled by the electric valve body. Pneumatic components ensure the sensitivity and stability of various actions during long-term use.

- Station linear movement mechanism:The servo mode is used to drive the linear guide to move the mode during the conversion of the mold, and the rotation position is precisely positioned to achieve precise and rapid movement.

- Servo movement system:The servo motor and driver are used, and the feed shaft is precisely driven by imported screw rods with high wear resistance, and the vibration is small.

- Coloring:The main body of the device is blue (Jisun color number JS-SK-003), and warning signs are placed on the parts involved in personal safety.

- Electric control cabinet:Using the CNC system, the air switch adopts domestic high-quality air switch, Schneider button, and other main electrical components such as select switches and intermediate relays are all OMRON products. The control circuit is provided with overload protection function.

- The installation of the electrical components of the equipment complies with the relevant national regulations and has a reliable grounding device. The terminals, contactors and small air switches in the electrical box are installed in the VDE standard V-groove. Each electrical component is clearly marked. The electric control cabinet uses all-plastic combing cabinets with wire trunking for clear wire numbers; the control panel is clean and the subtitles on the signs are clear and easy to see.

List of main parts and maintenance

- List of main accessories

| NO. | Name | Quantity | Brand |

| 1 | CNC system | 1 set | JISUN |

| 2 | Boring head | 1 set | HUNKUN |

| 3 | Three-phase asynchronous motor | 1 piece | GUANGZHOU MICROMOTOR |

| 4 | servo motor | 2 set | DELTA |

| 5 | Screw + rail | 2 set | TBI |

| 6 | Pneumatic Components | 1 batch | AIRTAC |

| 7 | Leakage switch | 1 piece | CHINT |

| 8 | Transparent shell fuse | 1 piece | CHINT |

| 9 | Switching power | 1 piece | MW |

| 10 | Electromagnetic contactor | 2 set | TAIAN |

- Check the air / oil pressure and the condition of each fastener daily to ensure reliable use.

- Regularly lubricate moving parts and keep the equipment tidy.

- Clean the dust of the equipment regularly to avoid affecting the operation and product quality.

- The normal working time of the equipment is calculated from 8-10 hours per day. If the working time is longer due to production, the inspection and update of wearing parts, motors and other accessories should be strengthened to ensure the stability of the equipment.

45 days after the prepayment.

Payment method

L/C or T/T

Services and other

- Product quality warranty for one year, (except for artificial or abnormal use) wearing parts are not included in the warranty scope. For details, please refer to the "wearing parts list" in the instruction manual.

- You are very welcome to visit our factory to see our machine how to work before you place an order with us.

- This product is delivered randomly: a manual and a set of molds (if other specifications are required, the cost will be quoted separately).

- If customer have any question about operation when using our machine,we will reply you by email/telephone/other online chat tool within 24 hours.

- The buyer needs to provide power voltage, compressed air gas source and grounding devices in accordance with electrical specifications on the site of the manufacturer's workshop; the buyer must configure the cables and air pipes connected to the equipment.

- The circulating cooling water, hydraulic oil (recommended to use 46 brand hydraulic oil), lubricating oil and cooling oil required by the equipment are purchased by the purchaser.